Our Bridges

Explore the evolution of our engineering excellence through decades of innovative steel bridge designs

Bridge Portfolio

A comprehensive showcase of our steel bridge designs and achievements over the years

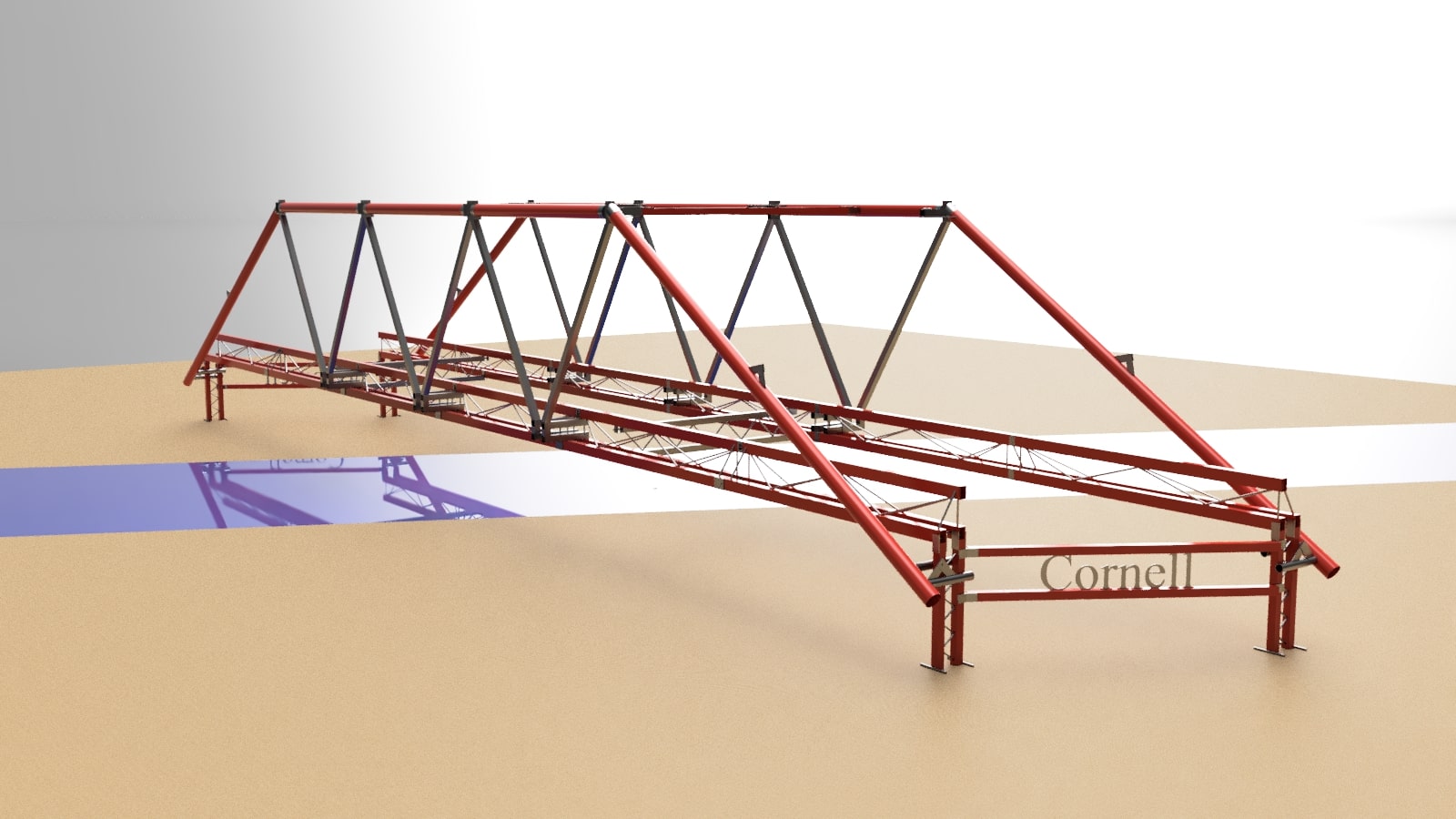

The 2025 bridge is an under-chord truss design that rethinks last year's upper-chord configuration, addressing previous load path inefficiencies with a more cost-effective approach. The structure features primarily double shear and single shear plate connections, chosen to overcome past issues with solid stock connections. Comprehensive analysis including a global stiffness matrix method with detailed limit state verifications via finite element analysis validated the design's reliability and strength before loading.

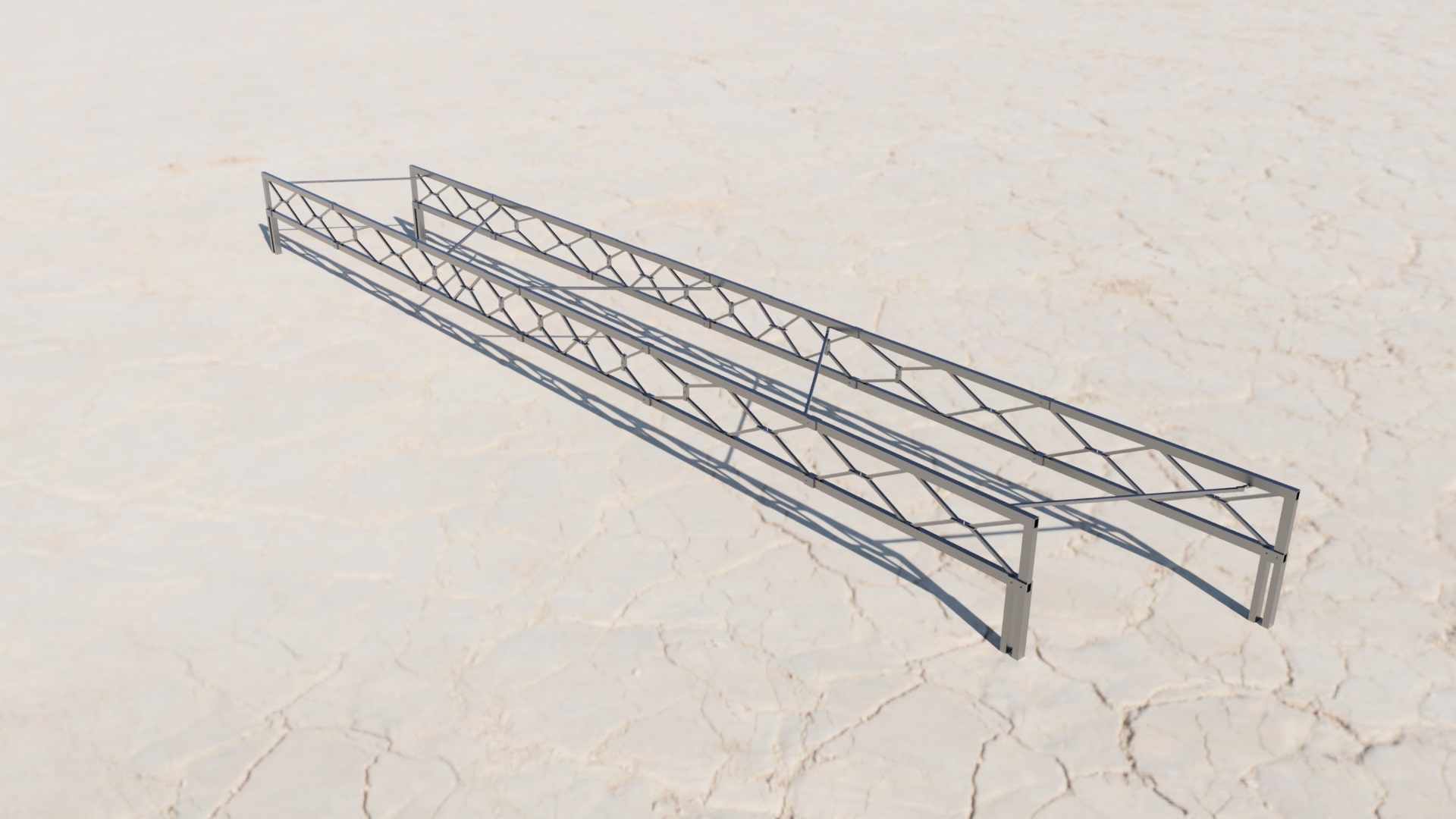

The 2024 bridge is a spaceframe span with a truss upper chord. The bridge was designed, fabricated, and welded in house like our previous bridges. This bridge was the first upper chord we have designed in over 5 years. The bridge featured primarily double shear connections in order to minimize the risk of bolt shearing under load. The bridge passed lateral loading, but deflected too much under vertical load. The bridge was unranked due to this issue.

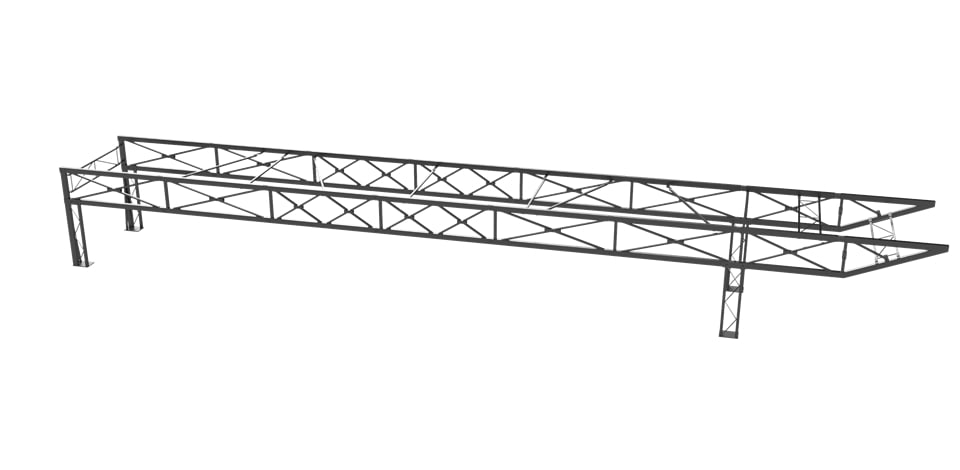

The 2023 bridge is a lower truss bridge composed of Warren trussing. This bridge was fabricated entirely in-house and features primarily solid stock connections and plated connections that abide by the returning faying surface rule. Some unique features of the bridge include a repeating truss design and simple leg design driven by not only the faying surface rule, but also the ease of building for construction. The bridge passed the lateral deflection test; but failed due to a bolt shear in the lower solid stock connection during the vertical load test.

The 2022 bridge is a lower truss bridge with a cantilever on one end. The bridge features double shear plates to abide by the faying surfaces rule, three-dimensional legs for stability and ease of construction, and numerous laterals at the cantilever end to assist with lateral deflection.

The 2021 bridge is an "entirely digital" bridge, for Cornell Steel Bridge participated in the 2021 Steel Bridge Supplemental Competition. The bridge drew inspiration from the 2019 bridge, but did have fundamental differences than its predecessor, such as the upper chord cantilever. Cornell Steel Bridge placed 2nd overall in the Supplemental Competition with this bridge (1st in Design & Video, 2nd in Analysis & Construction Sequencing). Our video submission for the Supplemental Competition can be found here.

The 2020 bridge was not presented to the public due to the COVID-19 global outbreak. Although the competition was cancelled, the bridge was close to finished. Overall, members on the team enhanced their design and analysis skills, fostered fabrication and welding experiences, and improved construction techniques and methods through their experiences in Steel Bridge this year.

The 2019 bridge was an upper truss bridge featuring double shear connections, triangle connections, and double-sided connection tubes. At competition, our bridge sustained the 2500-pound load without breaking. Despite not entering the top 3 places overall, the bridge achieved 2nd in aesthetics and was a challenge that we were able to complete.

The 2018 bridge was a lower truss with simple X-shaped braces. The bridge featured two different boltless connections that helped reduce our construction time from 14 minutes the previous year to 9 minutes.

The 2017 bridge was a cantilevered lower truss that included tube and channel connections in the diagonal bracing as well as moment-resistant double-shear connections in the top chord to stop out-of-plane buckling. Though a plug weld directly under the chosen load failed at competition, based on the results of our two successful tests our bridge was projected to place 1st in stiffness and 3rd overall.

The 2016 bridge featured a three-chord space frame as the lower chord of an upper truss bridge. This frame separated the upper truss from the decking rail to allow the newly introduced vehicle clearance template to pass through. If it had not been disqualified, the bridge would have taken 1st in display. The team also took 1st in presentations.

The 2015 bridge featured an open-hat top chord and space frame combined decking/bottom chord, and was able to support the prescribed load despite undergoing compressive flexure. Overlooking an easily avoidable dimensional penalty, the bridge was projected to place 3rd in Structural Efficiency and 4th in both Stiffness and Lightness.

The 2014 bridge distinguished itself as one of only a handful of lower, beam bridges to provide sufficient capacity for the prescribed load. At 10 minutes with 3 builders, our team took 1st place in both Construction Speed and Construction Economy.

With a sleek, single-layer design, the 2013 bridge took 1st place in Construction Economy and 2nd in Lightness. We were prevented from earning 2nd place Overall only by a dimensional penalty caused by a deformed connection.

Featuring twist-locking connections and a tall, thin-walled open-hat section decking, the 2012 bridge placed 3rd Overall and 1st in Stiffness.